Welcome to Our Company

D.A.S.A Material

Product Details:

- Color White

- CAS No 2873-97-4

- Molecular Formula C9H15NO2

- Grade Analytical Grade

- Composition Diacetone acrylamide

- Product Type D.A.S.A Material

- Storage Instructions Store in a cool, dry place, preferably in a tightly sealed container

- Click to View more

X

D.A.S.A Material Price And Quantity

D.A.S.A Material Product Specifications

- White crystalline powder

- Used as a reactive additive and crosslinking agent

- Store in a cool, dry place, preferably in a tightly sealed container

- 99%

- Diacetone Acrylamide (DAAM) and related compounds

- Powder

- Industrial raw material

- India

- Analytical Grade

- Diacetone acrylamide

- D.A.S.A Material

- White

- 2873-97-4

- C9H15NO2

D.A.S.A Material Trade Information

- MUMBAI

- Telegraphic Transfer (T/T)

- 1000 , Per Day

- 1 Week

- All India

Product Description

Technical Specification

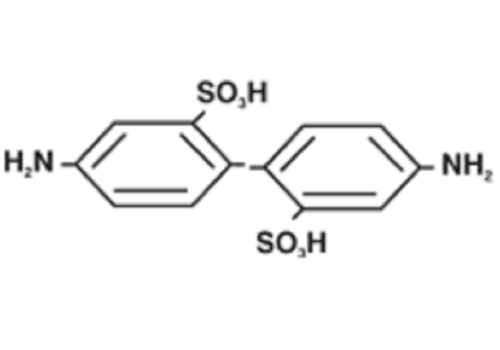

| SYNONYMS | 4:4 DIAMINO SULPHANILIDE |

| MOLECULAR WEIGHT | 263 |

| CAS NO. | 16803-97-7 |

| EMPIRICAL FORMULA : | C12H13N3O2S |

| PHYSICAL APPEARANCE : | LIGHT BROWN COLOURED DRY MATERIAL |

| PURITY (NITRITE VALUE) : | 95.0 % MINIMUM (M.W. 263) |

| INSOLUBLES IN DIL-HCL | 0.2 % MAXIMUM |

| PURITY BY HPLC | 96.00 % MINIMUM |

Exceptional Solubility and Functionality

DAAM's high solubility in water and organic solvents enables seamless integration into various industrial processes. As a reactive additive and crosslinking agent, its consistent composition enhances both the mechanical and chemical properties of end products, offering flexibility across multiple sectors.

Reliable Shelf Life and Storage Guidance

This material boasts a shelf life of 24 months when stored in a cool, dry environment and tightly sealed containers. Proper storage preserves its analytical grade purity, ensuring it remains effective for precise applications in research, manufacturing, and formulations.

FAQ's of D.A.S.A Material:

Q: How should Diacetone Acrylamide be stored to maintain its shelf life?

A: DAAM should be kept in a cool, dry place, inside tightly sealed containers to protect it from moisture and contamination. These conditions help ensure its shelf life of 24 months and maintain its purity and effectiveness for industrial use.Q: What are the typical industrial applications of DAAM material?

A: Diacetone Acrylamide is primarily used as a reactive additive and crosslinking agent in the production of polymers, resins, and specialty coatings. Its functionality enhances mechanical strength, durability, and resistance in various chemical formulations.Q: When is DAAM typically added during the manufacturing process?

A: DAAM is generally incorporated during the formulation phase of polymer or resin production, where its crosslinking properties facilitate the creation of stable molecular networks and improved product performance.Q: Where is DAAM sourced and who can supply it?

A: DAAM is manufactured, distributed, exported, and supplied by trusted companies in India known for delivering analytical grade materials. Indian suppliers ensure consistent quality suitable for research and industrial applications.Q: What benefit does the high purity of DAAM offer in industrial usage?

A: The 99% purity of DAAM ensures minimal contaminants in final products, promoting higher performance, reliability, and reproducibility in sensitive industrial and analytical processes.Q: How is DAAM used as a reactive additive in formulations?

A: DAAM's molecular structure allows it to actively participate in polymerization and crosslinking reactions, resulting in materials with superior strength, flexibility, and resistance to chemical degradation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free