Welcome to Our Company

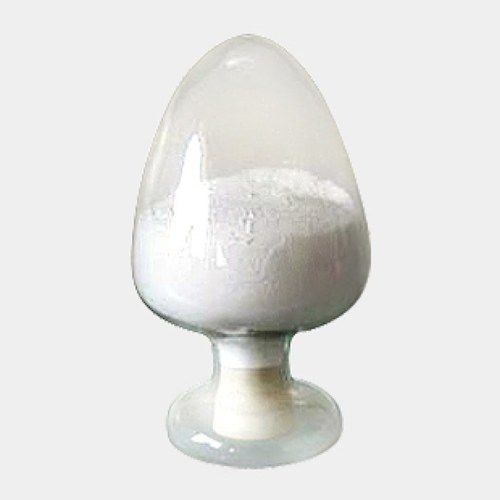

Silicified Microcrystalline Cellulose

100 INR/Kilograms

Product Details:

- Melting Point Decomposes before melting

- Structural Formula -(-C6H10O5-)n- + SiO2

- Molecular Formula (C6H10O5)n + SiO2

- Loss on Drying 5.0%

- Smell Odorless

- Particle Size 15-50 m

- EINECS No 269-587-0

- Click to View more

X

Silicified Microcrystalline Cellulose Price And Quantity

- 100.00 - 200.00 INR/Kilograms

- 100 INR/Kilograms

- 1000 Kilograms

Silicified Microcrystalline Cellulose Product Specifications

- 0.001%

- Cool, dry place, tightly sealed container

- Tablet binder, pharmaceutical formulations

- Variable

- 269-587-0

- 5 years

- Pharma Grade

- Silicified Microcrystalline Cellulose

- Insoluble in water and most organic solvents

- 39129090

- 4.5 7.0

- >99

- Tasteless

- White

- Pharmaceutical Excipient

- NO

- White powder

- 68333-16-4

- (C6H10O5)n + SiO2

- Powder

- Decomposes before melting

- -(-C6H10O5-)n- + SiO2

- Silicified Microcrystalline Cellulose

- 15-50 m

- 5.0%

- Odorless

Silicified Microcrystalline Cellulose Trade Information

- MUMBAI

- Telegraphic Transfer (T/T)

- 1000 Kilograms Per Week

- 1 Week

- Contact us for information regarding our sample policy

- All India

Product Description

Silicified Microcrystalline Cellulose

Silicified Microcrystalline Cellulose USP

Solution for Optimum Compatibility

Silicification of MCC increased physical properties such as true density, Hausner ratio, porosity, ejection force and specific surface area. Other properties such as bulk and tap densities were reduced due to the amorphous and light character of fumed silica.

Superior Tablet Binder and Disintegrant

Silicified Microcrystalline Cellulose enhances tablet strength while promoting rapid disintegration, ensuring fast and efficient drug release. Its high compressibility enables robust tablet formation even with minimal active ingredient concentrations. This excipient is especially valuable in direct compression and high-speed tablet production environments, where consistency and quality are critical.

Manufactured for Quality and Compliance

Produced under stringent GMP guidelines, this excipient meets USP, EP, and JP quality standards. Passes all pharmacopeia-required identification, microbial, and residue tests, guaranteeing product safety and consistency. Its long shelf life and stable physical properties make it reliable for both large-scale manufacturers and suppliers focused on global distribution.

FAQ's of Silicified Microcrystalline Cellulose:

Q: How does Silicified Microcrystalline Cellulose benefit pharmaceutical tablet formulation?

A: It provides superior compressibility and enhances disintegration, resulting in strong tablets that break down efficiently for rapid active ingredient release, making it ideal for high-quality pharmaceutical formulations.Q: What are the primary uses of Silicified Microcrystalline Cellulose in the pharmaceutical industry?

A: It is mainly used as a tablet binder and disintegrant in tablet production due to its free-flowing nature, high purity, and ability to improve both tablet integrity and dissolution properties.Q: When should this excipient be chosen over traditional microcrystalline cellulose?

A: Choose Silicified Microcrystalline Cellulose when you require enhanced compressibility, better flow properties, and optimal disintegration, especially in formulations involving direct compression or high-speed production lines.Q: Where is Silicified Microcrystalline Cellulose typically manufactured and supplied from?

A: It is produced, distributed, and exported by leading excipient manufacturers and suppliers in India, adhering to global quality standards and regulations.Q: What is the recommended storage condition and shelf life for Silicified Microcrystalline Cellulose?

A: Store it in a cool, dry place within tightly sealed containers. The product has a shelf life of five years, maintaining stability and quality when stored according to guidelines.Q: How is quality and regulatory compliance ensured for this excipient?

A: The product is manufactured under GMP guidelines and complies with USP, EP, and JP standards. It passes all required tests for identity, purity, microbial limits, and residue on ignition, ensuring safety and efficacy.Q: What is the process for integrating Silicified Microcrystalline Cellulose into tablet manufacturing?

A: It can be directly blended with active ingredients or other excipients due to its excellent flowability and compressibility. No pre-processing is necessary, making it suitable for direct compression and reducing formulation complexity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email