Sodium Carboxymethyl Cellulose pure /pharma/food grade

100 INR/Kilograms

Product Details:

- Particle Size 80-200 Mesh

- Loss on Drying Max. 10%

- HS Code 39123100

- Ph Level 6.0 - 8.5 (1% solution)

- Solubility Soluble in water, insoluble in organic solvents

- EINECS No 618-378-6

- Color White to off-white

- Click to View more

X

Sodium Carboxymethyl Cellulose pure /pharma/food grade Price And Quantity

- 1000 Kilograms

- 100 INR/Kilograms

- 400.00 - 500.00 INR/Kilograms

Sodium Carboxymethyl Cellulose pure /pharma/food grade Product Specifications

- White to off-white

- 618-378-6

- Soluble in water, insoluble in organic solvents

- 6.0 - 8.5 (1% solution)

- Non-poisonous

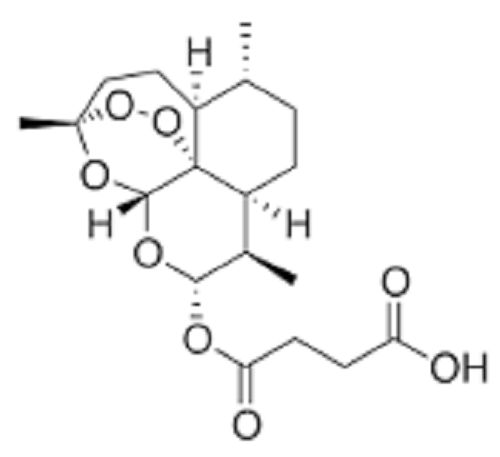

- C8H15NaO8

- Sodium Carboxymethyl Cellulose

- 9004-32-4

- 2 years from date of manufacture

- ~262.19 g/mol

- White to Off-White Powder

- 39123100

- Max. 10%

- 80-200 Mesh

- Pharmaceutical / Food Additive

- Pharmaceutical Formulations, Food Stabilizer, Thickener, Binder

- Odorless

- 99% Min.

- Tasteless

- Pure/Pharma/Food Grade

- Max. 20 ppm

- Decomposes upon heating

- Powder

- Store in a cool, dry place, away from moisture

- Sodium Carboxymethyl Cellulose

- [C6H7O2(OH)2OCH2COONa]n

Sodium Carboxymethyl Cellulose pure /pharma/food grade Trade Information

- MUMBAI

- Telegraphic Transfer (T/T)

- 1000 Kilograms Per Week

- 1 Week

- Contact us for information regarding our sample policy

- All India

Product Description

Sodium Carboxymethyl Cellulose pure /pharma/food grade

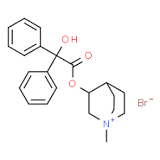

Croscarmellose Sodimu is used in oral pharmaceutical formulations as a disintegrant for and Granules. In tablet formulations Croscarmellose Sodium may be used in both direct-compassion and processes. When used in wet gradations the Croscarmellose Sodium is best added in boat the wet ar the process (intra and extra granularly) so that the wicking and swelling ability of the disintutilised. Concentrations of up as 5% W/W of Croscarmellose Sodium may be used as a tablet disinte normally 2% W/W is used in tablets prepared by direct compression and 3% W/W in tablet wet granulation process.

Versatile Applications in Pharma and Food

Sodium Carboxymethyl Cellulose is widely employed as a thickener, stabilizer, and binder in both pharmaceutical formulations and food products. Its compatibility with most water-soluble substances makes it a preferred additive for a variety of industries seeking consistent texture and enhanced stability.

Strict Quality and Regulatory Compliance

This product is manufactured according to rigorous quality protocols, ensuring compliance with FDA, USP, and NF standards. Microbial purity is guaranteed to meet pharmacopeial specifications, and each batch is allergen-free, delivering safe and reliable performance across medical and food applications.

Flexible Packaging and Long Shelf Life

Supplied in durable HDPE bags, fiber drums, or custom packaging solutions, Sodium Carboxymethyl Cellulose remains stable and effective when stored in a cool, dry environment. With a two-year shelf life from the date of manufacture, its quality and functionality are preserved for extended use.

FAQs of Sodium Carboxymethyl Cellulose pure /pharma/food grade:

Q: How is Sodium Carboxymethyl Cellulose used in pharmaceutical and food applications?

A: Sodium Carboxymethyl Cellulose acts as a thickener, stabilizer, and binder in pharmaceutical formulations and food products. In pharmaceuticals, it is employed to enhance tablet cohesion and control viscosity in suspensions, while in food, it stabilizes emulsions and improves texture.Q: What are the storage requirements to maintain product quality?

A: Sodium Carboxymethyl Cellulose should be stored in a cool, dry place, away from moisture and direct sunlight. Proper storage conditions help maintain its 2-year shelf life and preserve functional properties such as viscosity and solubility.Q: Which regulatory and safety standards does this product meet?

A: This product complies with FDA, USP, and NF requirements, ensuring it matches international safety and quality benchmarks. It is also allergen-free, non-poisonous, and meets pharmacopeial standards for microbial purity and heavy metal content.Q: When should I use Sodium Carboxymethyl Cellulose in a formulation?

A: Sodium Carboxymethyl Cellulose is ideal whenever a formulation requires effective thickening, improved stability, or binding properties, especially in water-based systems where compatibility and solubility are essential.Q: What are the key benefits of using Sodium Carboxymethyl Cellulose?

A: Key benefits include excellent water solubility, consistent viscosity (10003000 cps for a 2% solution), compatibility with water-soluble substances, allergen-free safety, and suitability for both pharmaceutical and food applications.Q: Where does the manufacturing and distribution of this product take place?

A: Sodium Carboxymethyl Cellulose is manufactured, supplied, and exported by certified distributors, manufacturers, and traders based in India, adhering to global standards in quality and packaging.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free