Welcome to Our Company

RESIST SALT

Product Details:

- Smell Odorless

- Molecular Weight 142.04 g/mol

- Other Names Resist Salt, Glaubers salt

- Storage Store in dry and cool place

- Structural Formula Na2SO4

- Poisonous Yes

- Density 2.66 Gram per cubic centimeter(g/cm3)

- Click to View more

X

RESIST SALT Price And Quantity

RESIST SALT Product Specifications

- Textile industry for resist dyeing

- Granular / Powder

- Completely soluble in water

- Na2SO4

- Powder

- 231-820-9

- Saline

- Industrial

- Decomposes

- Inorganic Salt

- IS/BIS Standard

- 28331100

- 98% min

- 7 (1% solution)

- Sodium Sulphate Base

- Sodium Sulphate

- 142.04 g/mol

- Resist agent, dyeing assistant

- Odorless

- Yes

- 2.66 Gram per cubic centimeter(g/cm3)

- 7757-82-6

- Resist Salt, Glaubers salt

- Store in dry and cool place

- Textile Auxiliaries

- Na2SO4

RESIST SALT Trade Information

- MUMBAI

- Telegraphic Transfer (T/T)

- 1000 , Per Week

- 1 Week

- All India

Product Description

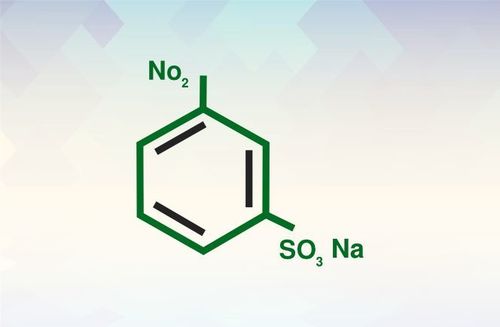

It is a primary dyestuff intermediate used in pigments and electroplating industry. It comes in wet cake form, powder form and small granular pills which is a non-dusting form. All forms can vary in quality and purity in terms of moisture and other insoluble content

| Chemical Name | - Sodium Meta Nitro Benzene Sulfonate - Meta Nitro Benzene Sulphonic Acid Sodium Salt - Meta Nitro Benzene Sulphonate |

| Synonyms | - Nitro Benzene 3 Sulphonic Acid Sodium Salt |

| Molecular Weight | - 225.2 |

| Chemical Formula | - CHONSN645a |

| Description | - White to light yellow powder |

| Purity | - 96% min |

| PH | - 6 to 9 |

| Solubility in 20% water | - Complete |

| Insolubles | - 0.1% max |

| Uses | - It is a principal dye intermediate for thesynthesis of amino anthraquinone, used in textile printing manufacturing chemicals for electroplating. |

| Packing | - Standard packaging size ranges from 20-50kgs depending on customer specifications jumbo bags range from 350-700kgs. |

| Hazard | - No health hazard |

| Storage | - Stable for years und |

Superior Textile Dyeing Assistance

RESIST SALT serves as a vital dyeing assistant in textile applications, providing optimal resist properties for effective color separation during the dyeing process. Its compatibility with most dyes, neutral pH, and saline nature ensure efficient results without compromising fabric quality. The product assists in achieving sharp patterns and maintaining vibrant colors.

Trusted Quality Standards

Manufactured and packed in adherence to IS/BIS standards, RESIST SALT is available in granular or powdered form. The product's high purity, minimal moisture and iron content, and stable chemical properties guarantee reliable performance. The odorless and non-poisonous formula offers safe handling and storage solutions for industry professionals.

Long Shelf Life and Safe Storage

Packed in robust HDPE bags with inner liners, RESIST SALT retains its quality for up to 24 months from the manufacturing date. Proper storage in dry, cool environments ensures extended usability, preventing contamination and preserving chemical integrity for consistent textile dyeing operations.

FAQ's of RESIST SALT:

Q: How should RESIST SALT be stored to maintain its quality?

A: RESIST SALT must be stored in a dry and cool place, ideally within its original HDPE packaging with an inner liner, to prevent moisture absorption and degradation over its 24-month shelf life.Q: What is the main benefit of using RESIST SALT in the textile industry?

A: As a resist agent and dyeing assistant, RESIST SALT ensures precise color separation and pattern formation during resist dyeing, enhancing the final quality and vibrancy of textile products.Q: When is RESIST SALT added during the textile dyeing process?

A: RESIST SALT is typically introduced during the initial stage of the resist dyeing process, acting as an agent to control dye uptake and facilitate the desired pattern outlining on the fabric.Q: Where can RESIST SALT be sourced, and who are the main suppliers?

A: RESIST SALT is supplied by distributors, exporters, manufacturers, and traders in India, who adhere to IS/BIS standards to provide reliable, high-quality products for textile applications.Q: What makes RESIST SALT compatible with most textile dyes?

A: Its chemical structure and neutral pH (7 for a 1% solution) make RESIST SALT highly compatible with a majority of textile dye formulations, enabling uniform application and minimizing unwanted chemical interactions.Q: How is RESIST SALT used in the dyeing process?

A: RESIST SALT is dissolved completely in water and applied to textiles as part of the resist dyeing technique, where it helps block dye penetration in specific areas, allowing for distinctive designs.Q: What safety precautions should be taken when handling RESIST SALT?

A: Since RESIST SALT is non-poisonous and odorless, standard industrial precautions such as using gloves and protective clothing, and handling it in well-ventilated spaces, are sufficient for safe usage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free